x-tec® CO 4070 – Our universal classic for all corrosion problems!

x-tec® CO 4052 – For industrial use for small parts and coil!

x-tec® CO 4059 – Black and beautiful!

x-tec® CO 4057 – Active protection even at temperatures up to 500 °C!

x-tec® ECO 4061 – The water-based solution against rust!

x-tec® ECO black 4048 – Water-based and black!

x-tec® CO 4051 – The alternative to hot galvanising!

x-tec® CO 4060 – Passivation for zinc!

x-tec® CO 4046 – Transparent corrosion protection for pre-weathered zinc on coil!

x-clean® AF 4095 – Transparent scratch-resistant corrosion protection for

aluminium

coil!

Chromium-free coating materials containing metal pigments for the protection of metals against corrosion

x-tec® CO 4070

Our universal classic for all corrosion problems!

Solvent-based silver zinc flake coating with very good corrosion protection on steel, cast iron and other components made of iron

- Dip or spray application, also aerosol spray

- Thermal hardening from room temperature to 300 °C possible, also inductive

- The solid is approx. 56 %.

- With an applied minimum coating thickness of

10 to 15 µm, > 1,300 h are achieved in the neutral salt spray test (DIN EN ISO 9227) without results

respectively C5 according to classification of data sheet MB434 of the Stahl-Informations-Zentrum.

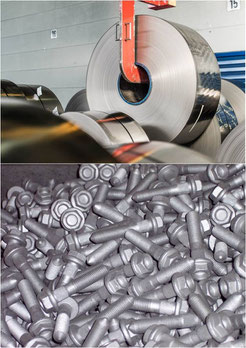

x-tec® CO 4052

For industrial use for small parts and coil!

Solvent-based silver zinc flake coating with very good corrosion protection on steel, cast iron and other components made of iron

- Dip-spin coating

- Coil coating

- Thermal hardening from 130 °C to 300 °C possible, also inductive

- The solid is approx. 56 %.

- With an applied minimum coating thickness of

10 to 15 µm, > 1,300 h are achieved in

the neutral salt spray test (DIN EN ISO 9227) without results respectively C5

according to classification of data sheet MB434 of the

Stahl-Informations-Zentrum.

x-tec® CO 4059

Black and beautiful!

Solvent-based black zinc flake coating with very good corrosion protection on steel, cast iron and other components made of iron

- Dip-spin coating

- Coil coating

- Spray application, also aerosol spray

- Thermal hardening from room temperature to

300 °C possible, also inductive

- The solid is approx. 50 %.

- With an applied minimum coating thickness of

10 to 15 µm, > 750 h are achieved in

the neutral salt spray test (DIN EN ISO 9227) without results

respectively C3/C4 according to classification of data sheet MB434 of the Stahl-Informations- Zentrum.

x-tec® CO 4057

Active protection even at temperatures up to 500 °C!

Solvent-based silver zinc flake coating with very good corrosion protection on steel, cast iron and other components made of iron and a temperature resistance up to 500 °C!

- Dip or spray application, also aerosol spray

- Thermal hardening from room temperature to

300 °C possible, also inductive

- The solid is approx. 56 %.

- With an applied minimum coating thickness of 10 to 15 µm, > 1,300 h are achieved in the neutral salt spray test (DIN EN ISO 9227) without results respectively C5 according to classification of data sheet MB434 of the Stahl-Informations-Zentrum.

x-tec® ECO 4061

The water-based solution against rust!

Water-based silver zinc flake coating with very good corrosion protection on steel, cast iron and other components made of iron

- Dip or spray application

- Thermal hardening from 80 °C to 300 °C possible, also inductive

- The solid is approx. 50 %.

- With an applied minimum coating thickness of

10 to 20 µm, > 1,300 h are achieved in the neutral salt spray test (DIN EN ISO 9227) without results respectively C5 according to classification of data sheet MB434 of the Stahl-Informations- Zentrum.

x-tec® ECO black 4048

Water-based and black!

Water-based black zinc flake coating with very good corrosion protection on steel, cast iron and other components made of iron

- Dip or spray application

- Thermal hardening from 80 °C to 300 °C possible, also inductive

- The solid is approx. 60 %.

- With an applied minimum coating thickness of 10 to 20 µm, > 750 h

are achieved in the neutral salt spray test (DIN EN ISO

9227) without results respectively C3 to C4 according to classification of data sheet MB434

of the Stahl-Informations-Zentrum.

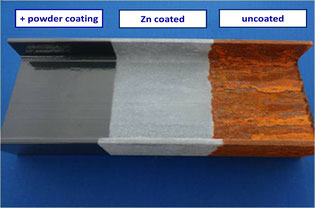

Recoatable, active, water-based zinc primer for lacquers and powder coatings

x-tec® CO 4051

The alternative to hot galvanising!

Water-based zinc flake primer for the overcoating with lacquer or powder coating for steel components

- Dip or spray application

- Thermal hardening from 80 °C to 180 °C

- The solid is approx. 75 %.

- With an applied minimum coating thickness of 20-25 µm, 1,300 h are achieved with powder top coat in the neutral salt spray test (DIN EN ISO 9227) without results respectively C5 according to classification of data sheet MB434 of the Stahl-Informations-Zentrum.

Passivation for zinc (painting, spraying)

x-tec® CO 4060

For the protection against white rust!

Air-drying, solvent-based clear coat with very good corrosion protection on zinc and galvanised components

- Brush or spray application

- Hardening at room temperature

- The solid is approx. 80 %.

- With an applied minimum coating thickness of 10 to 20 µm,

the formation of white rust will be prevented for many years.

Passivation for pre-weathered zinc (coil)

x-tec® CO 4046

For a nice homogeneous appearance!

Corrosion protection for zinc and pre-weathered zinc

- Coil coating

- PMT 200-250 °C

- The solid is approx. 30 %.

- The formation of white rust will be prevented for

long time.

- Can be coloured

- Active modifications are also possible (near the coast).

Passivation for aluminium

x-clean® AF 4095

So that the gloss will be preserved for a long time!

Corrosion protection for aluminium and polished aluminium

- Coil coating

- PMT 200-250 °C

- The solid is approx. 30 %.

- The formation of white rust will be prevented for long time.

Theodor-Heuss-Straße 11a

D-66130 Saarbrücken-Güdingen

Geschäftsführer: Dr. Stefan Sepeur, Reimund Krechan

Telefon: +49 (0)681 95940-0

Telefax: +49 (0)681 95940-15

E-Mail: info@nano-x.de

Registergericht: Amtsgericht Saarbrücken, HR B 12461

Umsatzsteuer-Identifikationsnummer: DE 203256653

Es gelten die Allgemeinen Geschäftsbedingungen der NANO-X GmbH (AGB's).